Blog

Top 10 Tips for Choosing the Right Wire and Cable?

Selecting the perfect wire and cable can be a daunting task. The wire and cable industry is vast, with a multitude of options available. According to a report by Grand View Research, the global wire and cable market is expected to reach over $300 billion by 2025. This growth showcases the increasing reliance on these essential components in various sectors.

Expert Mark Johnson highlights the importance of this decision. He states, "Choosing the right wire and cable can make or break a project." His insight underlines the critical impact that proper selection has on safety and functionality.

Factors like insulation type and gauge are crucial. Each project has unique demands. Many people overlook these elements, leading to costly mistakes. It’s vital to consider end-use conditions and electrical requirements. The wrong choice can result in hazards or inefficiencies. Understanding specifications is key to making informed decisions in the wire and cable landscape.

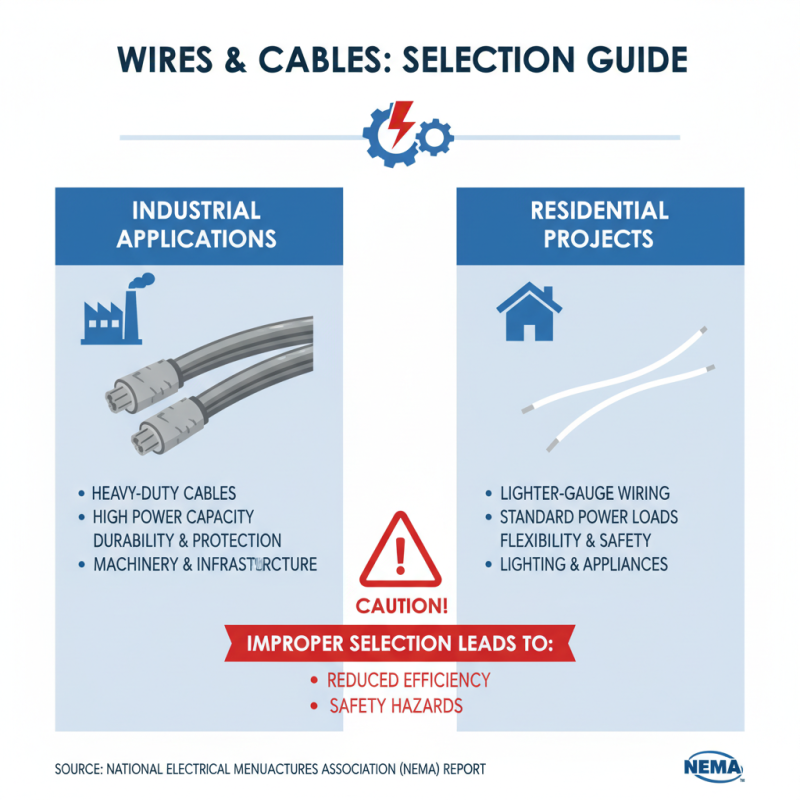

Understanding Different Wire and Cable Types for Your Needs

When selecting wires and cables, understanding the various types available is crucial. Different applications require specific specifications. For example, industrial settings often rely on heavy-duty cables, while residential projects may use lighter gauge wiring. According to a report by the National Electrical Manufacturers Association, improper wire selection can lead to reduced efficiency and safety hazards.

Tip: Always consider the wire's insulation and rating for your specific environment. For instance, PVC is great for indoor use, while thermoplastic rubber is suitable for outdoor scenarios.

Certain wire types, like coaxial or fiber optic, serve unique purposes. Coaxial is often used for television connections, while fiber optic cables are essential for high-speed internet. Research suggests that fiber optics can transmit data over long distances with minimal loss, making them vital as technology advances.

Tip: Check local regulations and standards. Compliance ensures safety and efficiency. Ignoring these may lead to costly issues down the line. Always keep your project’s needs in focus, assessing factors like electrical load, distance, and environmental conditions.

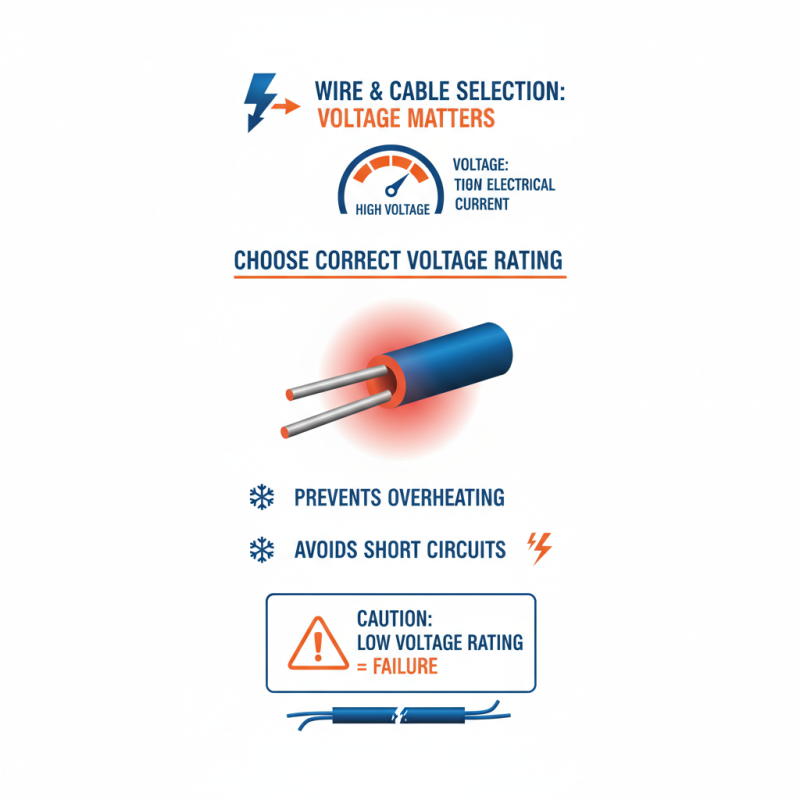

Evaluating Voltage and Current Requirements for Safety and Efficiency

When choosing the right wire and cable, understanding voltage and current requirements is crucial. Voltage indicates the force pushing electrical current through a circuit. Choosing a wire with the correct voltage rating helps prevent overheating or potential short circuits. For instance, using a wire rated for less voltage than required can lead to failure.

Current is equally important. It measures the flow of electricity. Selecting a wire that cannot handle the required current could lead to insulation breakdown. Always check ampacity ratings. This tells you how much current the wire can safely carry. A wire that appears fine may still underperform if pushed beyond its limits.

Do not overlook the environment where the wire will be used. Exposure to moisture or chemicals can degrade wire quality. Be prepared for unexpected challenges. Poor wire choice might lead to costly repairs. Reflect on what you prioritize in your project. Make informed decisions to ensure safety and efficiency in your electrical installations.

Considering Environmental Factors and Installation Conditions

When selecting the right wire and cable, environmental factors are crucial. Consider temperature variations. Extreme heat or cold can affect wire performance. For outdoor installations, look for cables resistant to moisture and UV exposure. These elements can degrade materials over time.

Installation conditions also play a significant role. Think about the spaces where cables will run. Tight spaces or high-traffic areas may require cables with better flexibility and durability. Improper handling can lead to damage. Even minor kinks can impact performance later.

Evaluate the potential for electromagnetic interference. If wires are near heavy machinery, choose shielded options. This decision can prevent signal loss. It’s easy to overlook these details in the planning phase. Yet, overlooking environmental and installation factors can lead to costly mistakes.

Assessing Wire and Cable Insulation Materials and Specifications

When assessing wire and cable insulation materials, it's crucial to consider their durability and resistance properties. Different environments demand specific materials. For example, PVC is versatile but not ideal for extreme temperatures. Meanwhile, cross-linked polyethylene (XLPE) offers better thermal stability. According to a recent industry report, about 40% of failures in cable systems relate to insulation issues. Understanding these factors can help prevent costly repairs.

Tip 1: Always verify the insulation ratings. They guide performance in heat, moisture, and chemicals.

Tip 2: Look for certifications that meet industry standards. These certifications ensure quality and safety.

Moreover, consider the dielectric strength of materials. High dielectric strength indicates better performance in electrical applications. Some materials may be effective but can also degrade over time, leading to failures. An investigation showed that 25% of electrical fires result from insulation breakdown. It's essential to regularly evaluate the insulation and replace any degraded components before they fail.

Comparing Costs and Lifespan for Cost-Effective Choices

When selecting wire and cable, costs and lifespan are crucial considerations. Data shows that a higher upfront cost can lead to significant savings over time. For instance, copper wire has a longer lifespan compared to aluminum. Research indicates that copper wires last up to 30 years, while aluminum may only last about 15 years.

Cost is another vital aspect. In recent industry reports, copper wire costs about 30% more than aluminum. However, the longer lifespan can offset the initial investment. A study identified that over 20 years, the total cost of ownership for copper could be lower due to less frequent replacements and maintenance.

Choosing the right material is essential. Often, decisions are made based solely on price. This can lead to larger expenses later. For example, using lower-quality materials may save money today but could fail sooner. This reflects the need for careful consideration, weighing immediate costs against long-term benefits. Reflecting on these choices is often overlooked but necessary for effective planning.

Cost Comparison of Different Wire Types

This chart displays the cost per meter of various wire types, helping to illustrate the differences in price which can influence cost-effective choices when selecting wiring options.

Related Posts

-

2025 How to Optimize Cable and Harness Assembly for Maximum Efficiency

-

Essential Checklist for Global Buyers to Navigate the Wire and Cable Industry Trends and Standards

-

Exploring the Evolution of Cable Wire: From Minimalist Designs to High-Tech Innovations

-

Top 5 Benefits of Using Copper Cables: Why They Outperform Fiber Optics in Most Applications

-

2025 Market Insights: 5 Essential Tips for Succeeding in Best Wire Harness Assembly

-

Maximize Safety and Efficiency: Choosing the Right Electric Cable Wire for Your Projects

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.