Blog

Essential Cable Harness Tips for Efficient Wiring Solutions?

In today's fast-paced world, efficient wiring solutions are crucial. A well-designed cable harness can streamline complex connections. It organizes wires, reducing clutter and the potential for errors. Choosing the right materials and layouts can enhance functionality.

However, crafting a cable harness is not without its challenges. Mistakes in design can lead to wasted resources and time. For instance, using poor-quality connectors can result in failure during use. It's essential to evaluate each component carefully.

Additionally, testing is often overlooked in the process. Conducting thorough checks can prevent future issues. A simple oversight might cost significantly in repairs. Reflecting on these aspects can lead to better practices in cable harness design. Ultimately, thoughtful planning translates into efficient and reliable wiring solutions.

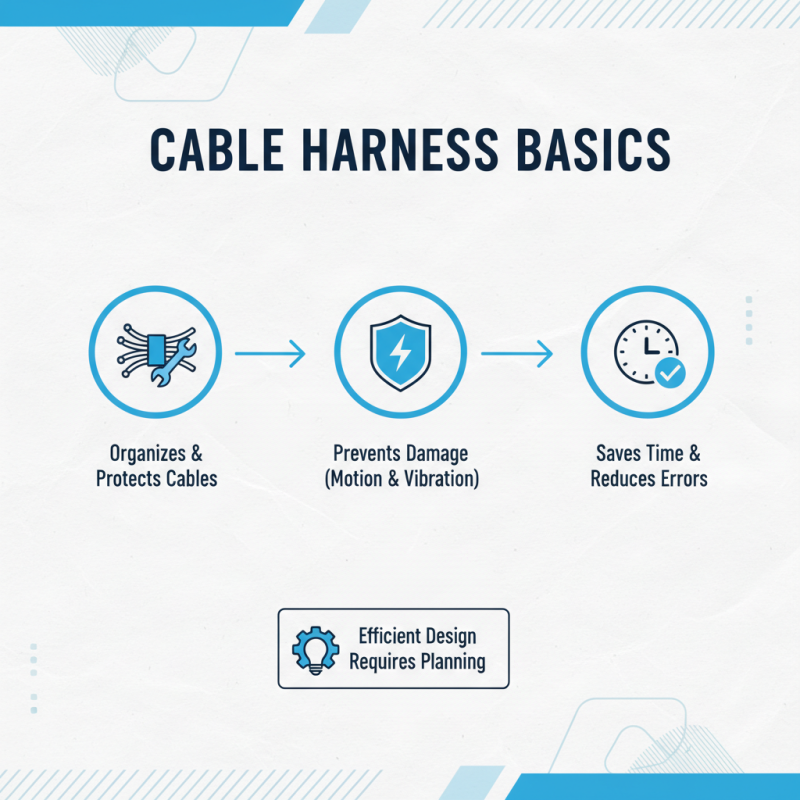

Understanding Cable Harness Basics for Effective Wiring

Understanding cable harness basics is crucial for effective wiring solutions. A cable harness organizes and protects electrical cables. This structure prevents damage during movement and vibration. In many applications, cable harnesses save time and reduce errors during installation. However, creating an efficient harness requires careful planning.

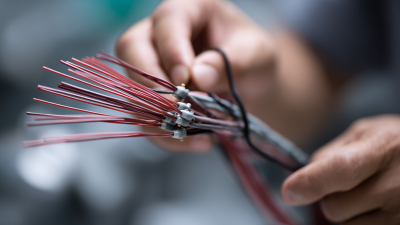

Designing a cable harness involves several factors. You need to determine the cable types, lengths, and connections necessary for the project. Mismatched cable sizes can cause issues. Not factoring in space also leads to complications. Too little room may mean a tight fit, while too much can create clutter. Testing different configurations can help find the right balance.

Working with cable harnesses can be a learning experience. Sometimes, mistakes happen. A poorly arranged harness can lead to maintenance nightmares. It's vital to review wiring regularly. This helps ensure everything functions properly over time. Keep an open mind to adapt your designs based on experience. Embrace the challenges that come with creating efficient wiring solutions.

Choosing the Right Materials for Cable Harness Construction

When selecting materials for cable harness construction, durability is key. Choose materials that can withstand environmental stresses. For example, rubber and PVC provide excellent insulation and flexibility. They can also resist moisture, making them ideal for outdoor applications.

Tips: Consider the working temperature range. Materials should perform well under extreme conditions. For high-temperature applications, silicone may be a better option. Always balance cost and quality. Sometimes the cheapest materials lead to failures.

Another point is weight. Lightweight materials can reduce overall project weight. This factor is crucial for aerospace or automotive applications. However, don’t sacrifice strength for weight. Reflect on whether your choices meet the project requirements.

Finally, evaluate your design. Often, the wrong material can slow down the assembly process. Choose pre-terminated cables to simplify installation. It may seem more expensive initially but can save time and labor costs in the long term.

Best Practices for Designing and Layout of Cable Harnesses

Designing cable harnesses is crucial for efficient wiring solutions. An industry report states that improper layouts can increase installation time by up to 40%. This statistic highlights the importance of thoughtful design.

When creating a layout, prioritize accessibility. Each connection should be easy to reach. A cluttered design often leads to mistakes. Additionally, using consistent color coding for wires can help avoid confusion. Simple choices can enhance clarity and reduce errors.

Another key aspect is the selection of materials. Using high-quality insulation can prevent failures. A breakdown in insulation can lead to costly repairs. Surveillance of constant wear during testing can also yield insights. Regular assessments may uncover weaknesses. Not all designs will work flawlessly on the first attempt. Flexibility in design allows room for improvements and learning.

Essential Cable Harness Tips for Efficient Wiring Solutions

Common Challenges in Cable Harness Production and Solutions

Cable harness production faces various challenges that can impact efficiency. A recent industry report indicates that 45% of manufacturers experience issues related to miscommunication during assembly. This communication gap often leads to costly mistakes. Clear documentation and regular updates can mitigate some of these risks, yet many companies still struggle in this area.

Another common issue is material quality. According to a survey, nearly 30% of assembly errors stem from using subpar materials. Poor insulation or inadequate shielding results in system failures. Investing in higher quality materials may seem costly upfront but saves money on repairs later. Companies often overlook the long-term benefits of reliable components for their wiring solutions.

Logistics also plays a crucial role. Delays can disrupt production schedules significantly. On average, a delay can cost a company up to 12% of its monthly revenue. An efficient inventory system and just-in-time delivery can alleviate this problem. Nonetheless, achieving this level of efficiency remains a challenge for many manufacturers. They often underestimate the complexity of managing supply chains, leading to repeated setbacks.

Essential Cable Harness Tips for Efficient Wiring Solutions

| Challenge | Cause | Solution | Impact |

|---|---|---|---|

| Poor Wire Connections | Inadequate crimping or soldering techniques | Implement quality control measures and training | Reduces failure rates and enhances reliability |

| Complex Routing | Inefficient design layout | Utilize CAD tools for optimized design | Improves installation speed and reduces errors |

| Insufficient Protection | Lack of protective coverings or sheaths | Select suitable materials for environmental protection | Enhances durability and ensures safety |

| Overheating | Excessive current load | Use appropriate gauge wires for current requirements | Prevents component failure and fire hazards |

| Cable Aging | Degradation of materials over time | Regular inspection and use of high-quality materials | Extends lifespan and maintains performance |

Testing and Quality Control Measures for Cable Harnesses

Testing and quality control measures are crucial in the manufacturing of cable harnesses. According to industry reports, up to 30% of cable harness failures occur due to improper testing methods. Thorough inspection processes can mitigate these risks significantly. Implementing effective testing strategies helps ensure reliability and functionality in a variety of applications.

A few essential tips for quality testing include visual inspections and continuity tests. Visual inspections should check for loose connections or insulation damage. Continuity tests can help identify breaks in wiring. Moreover, using automated testing equipment can enhance accuracy. However, not all manufacturers prioritize these steps. Some may overlook them, leading to potential failures.

Regularly assessing your testing protocols is vital. Keeping records of past tests helps analyze trends over time. This can reveal areas needing improvement. Furthermore, investing in employee training ensures everyone understands the quality control importance. Such investment pays off in reduced failures. Remember, quality matters, and it can’t be an afterthought in cable harness production.

Related Posts

-

Comparing Wire Harness Assemblies: Which Cable Solutions Meet Industry Standards Best?

-

2025 How to Optimize Cable and Harness Assembly for Maximum Efficiency

-

10 Best Industrial Wire Trends You Should Know in 2023

-

How to Efficiently Design Your Own Wire Harness Assembly

-

Top 10 Benefits of Using a Wire Puller for Your Wiring Projects

-

The Ultimate Guide to Sourcing High-Quality Coaxial Cables for Your Business Needs

© 2023 JEM Electronics, Inc. – United States Cable Assembly. All rights reserved.